Applications

These units have been specifically designed and developed for a number of industries, including:

● Commercial

Computer Rooms, Server Rooms, Dealing Rooms and Showrooms.

● Process Areas

Control Rooms, Electronic Manufacturing, CD Manufacturing and Injection Moulding Facilities.

● Environmental Control Archive Storage, Museums, Libraries, Art Galleries, Testing & Measurement Laboratories and Textile Laboratories.

● Telecommunications

Internet Farms and Switch Rooms.

● Industrial

Petrochemical, Manufacturing Areas and Airports.

● Medical

Clean Rooms and Medical & Pharmaceutical Facilities.

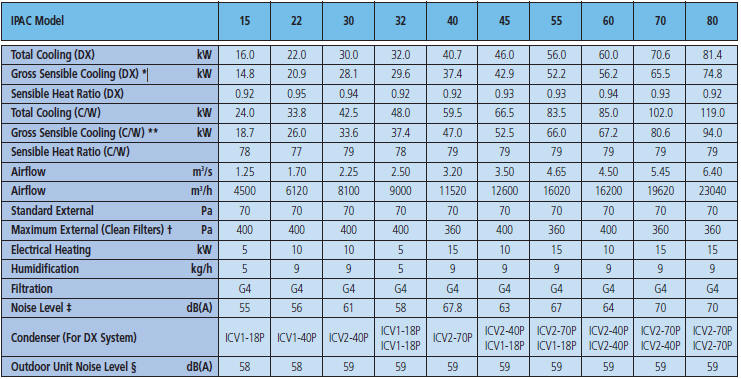

* Unit ratings at 24 °C / 50 % RH Internal and 35 °C External. ** Unit rating at 24 °C / 50 % RH and chilled water 7 °C Flow / 12 °C Return.

† Maximum external pressure would be optional via a pulley / motor change (client to specify at time of order).

‡ Sound pressure level per cabinet at a distance of 3 m from the unit with floor return and ducted supply.

§ Sound pressure level per condenser at a distance of 3 m from the unit.

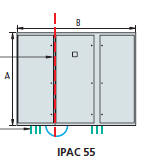

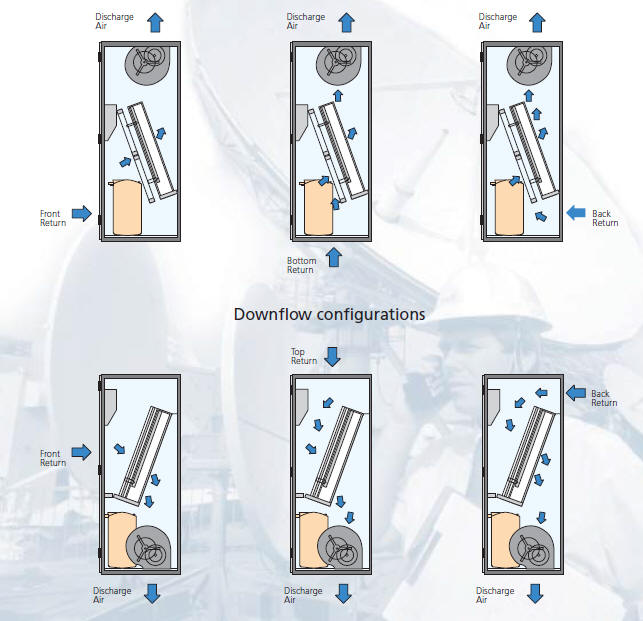

Downflow Units

● Top return air inlet, with bottom outlet air supply (standard).

● Front return air inlet, with bottom outlet air supply (factory fit option).

● Back return air inlet, with bottom outlet air supply (site- configurable).

A variety of header boxes and base plinths can be supplied to suit the above units.

DUAL CABINET UNIT SPLIT LINE. CABINETS SHOWN SIDE BY SIDE FOR CLARITY.

NOTE: CABINETS CAN BE POSITIONED APART TO SUIT ROOM LAYOUT.

DUAL CABINET UNITS HAVE DX OR C/W AND DRAIN CONNECTIONS TO EACH CABINET.

INTERCONNECTING POWER AND CONTROL CABLING VIA SIDE PANEL GLAND PLATES OR UNDER FLOOR.

ABU DHABI +971 2 5557351

+974 44150543

DOHA

QATAR

UAE

OMAN

MUSCAT

+968 24 750205

+971 4 3352995

+971 4 8831401

JAFZA

DUBAI

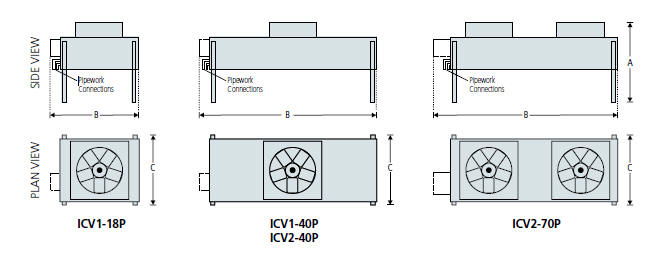

Please note: the condensers can be used in both horizontal and vertical airflow modes. Condensers are fitted with isolator and pressure actuated fan speed

controller as standard

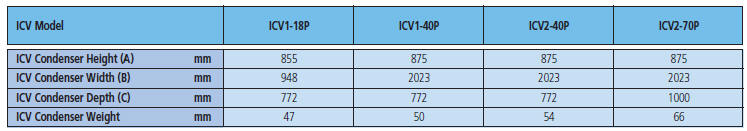

ICV condenser dimensions and weights

Internal unit colour BS00A05 (nearest equivalent RAL 7035).

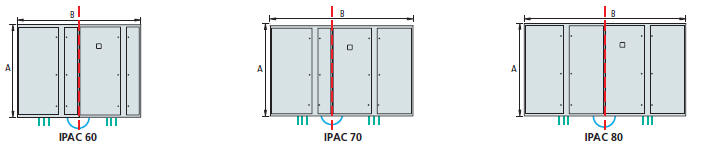

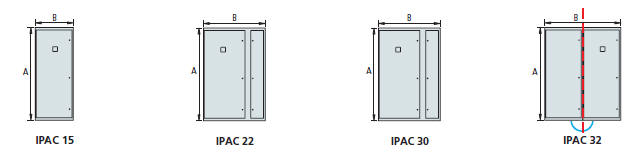

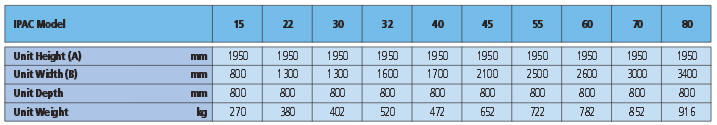

Internal unit dimensions and weights

Technical Specifications

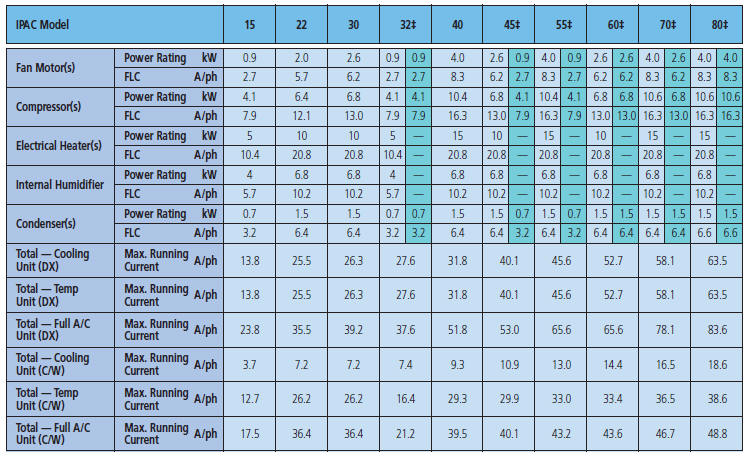

Range electrical details

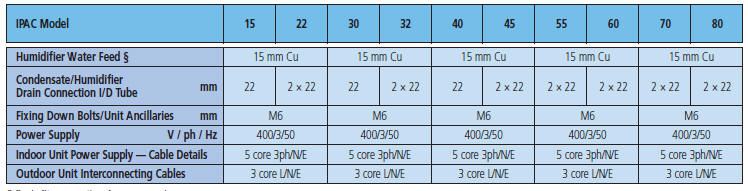

General Service Connections

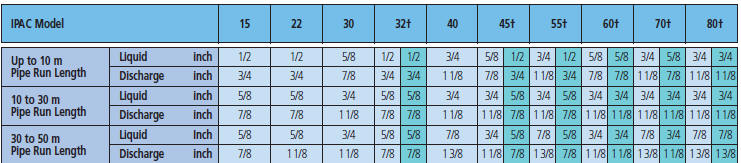

layout/conditions. † Dual cabinet units have two sets of interconnecting pipework

Pipework line sizes guide

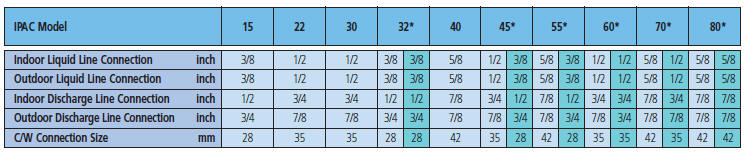

Pipework connection sizes

Technical Specifications

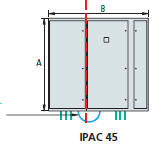

Upflow configurations

Upflow Units

● Bottom return air inlet, with top outlet air supply (standard).

● Front return air inlet, with top outlet air supply (factory fit option).

● Back return air inlet, with top outlet air supply (site- configurable).

Airflow Configuration

Air Quality and Distribution

The IPAC range is fitted with EU4 filters to provide air quality control,

with the option of EU, EU7 (higher filtration levels are available, but will

be located in an external filter

section).

The

units

are

fitted

with

a

fan/motor

combination

capable

of

supplying

the

design

airflow

against the

external

resistance

of

a

typical air distribution system

as well as

providing a quantity of fresh air into

the

conditioned

space.

All Year Round Operation

IPAC units are designed to operate

24 hours a day, all year round, in any mode (i.e. cooling/heating/ dehumidification/humidificati

on) and come complete with condenser fan speed and pressure control to avoid problems associated with over condensing during winter cooling.

Cooling, Cooling with Heating or Full Air Conditioning

Different applications require different modes of control and the IPAC range is available in three basic configurations:

● Cooling only (cooling unit).

● Cooling with heating

(temperature unit).

● Cooling with heating and humidification/dehumidification

Air-Cooled Condensers

A matched range of air cooled condensers are available for operation in ambient temperatures up to 35 °C. However, for higher ambients, uprated air-cooled condenser(s) can be supplied.

Ease of Maintenance

![]()

![]() In

rugged

environments

in

which

air conditioning

units

are

installed

it

is

In

rugged

environments

in

which

air conditioning

units

are

installed

it

is

![]() essential

to

carry

out

regular

maintenance

for

optimum performance.

As well

as

using

top quality

components,

ease

of maintenance

has

been

designed

into

these systems.

The

controller

automatically indicates

when maintenance

is

required

on

individual components and all servicing

can

be

carried

out

through

the

front

door(s)

of

the

unit.

essential

to

carry

out

regular

maintenance

for

optimum performance.

As well

as

using

top quality

components,

ease

of maintenance

has

been

designed

into

these systems.

The

controller

automatically indicates

when maintenance

is

required

on

individual components and all servicing

can

be

carried

out

through

the

front

door(s)

of

the

unit.

Selecting a System

The overall building services design will define the type of cooling system required. As standard, the

IPAC range is available in three basic systems:

● Direct expansion cooling with air-cooled condenser.

● Direct expansion cooling with water-cooled condenser.

● Chilled water coolingAir Quality and Distribution

The

IPAC

range is

fitted

with

EU4 filters

to

provide

air

quality

control, with

the

option

of

EU,

EU7

(higher filtration

levels

are

available,

but

will

be

located in

an

external

filter

section).

The

units

are

fitted

with

a

fan/motor

combination

capable

of

supplying

the

design

airflow

against the

external

resistance

of

a

typical air distribution system as

well as

providing a quantity of fresh air into

the

conditioned

space.

All Year Round Operation

IPAC units are designed to operate 24 hours a day, all year round, in any mode (i.e. cooling/heating/ dehumidification/humidificati

on) and come complete with condenser fan speed and pressure control to avoid problems associated with over condensing during winter cooling.

Temperature Control

IPAC units are designed to operate at room temperatures from 18 °C to

30 °C as standard and with factory added options can operate outside this range. Temperature can be precisely controlled, with cooling provided by a chilled water system or a DX unit with an external air-cooled condenser (option of water-cooled condenser available). Where heating is required, the alternatives of electric or low pressure hot water heating are available.

Humidity Control

Where humidity control is required, the IPAC unit is factory fitted with the facility whereby the cooling coil is operated below the dew point of the conditioned air to provide dehumidification. To ensure optimum temperature control in conjunction

with dehumidification the options of hot gas or electric reheat are available.

The unit can also be fitted with a proportional output humidifier to provide clean sterile steam. The humidifier responds to a changing demand using the water level (WL) system of modulation. Output is varied by increasing or decreasing the level of water in the cylinder. A decrease in water volume causes less electrical energy (measured in amperes) to pass between the electrodes, transforming less water into steam. An increase in water volume, logically, has the opposite effect. WL can modulate down to 20 % of full output.

Controller

The Eaton-Williams controller is a purpose designed LonWorks™ microprocessor, which fully complies with EEC directives for electromagnetic compatibility (EMC).

The controller is powered from a

9 V and 24 V 50 Hz power supply, these are provided via a transformer mounted within the electrical chassis.

All outputs are protected by shrouded fuses.

The Controller Hardware

Consists of:

● Display and push-button assembly.

● Microprocessor controller assembly.

The Controller Includes the

Following Features as Standard:

● Temperature and humidity set point adjustment.

● Dead band adjustment.

● Proportional band adjustment.

● Alarm band adjustment (individually for temperature and humidity).

● Fault and service alarm volt-free contacts.

● Winter low pressure switch delay timer adjustment.

● Start delay timers.

● Historical alarm logging.

● Lon network communications.

● Stand-alone or Master/Slave.

![]()

![]() ●

Run/Standby

and

duty

rotations.

●

Run/Standby

and

duty

rotations.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Duty

Range

Duty

Range

The IPAC range has been developed to provide a flexible duty range of units.

● Stand alone units currently range from a nominal 15 kW to 80 kW.

● Master/Slave combinations extend the range for larger applications.

Precision Air Control Equipment

The IPAC floor standing units are in their most basic form available in chilled water or DX cooling only configuration. These systems can either be mounted inside the conditioned space or mounted remotely, with the fan developing external pressure to transport the air to the conditioned space. Units can be manufactured with an upflow or downflow air pattern to enable optimum comfort levels. Depending on the application, heating, dehumidification, humidification and air filtration can also be provided.

As well as the standard unit configurations, a variety of options can be factory or site-fitted to customise units to the system requirements. This provides the designer, installer and customer with a system that can precisely match the requirements.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

The Invicta Precison Air Control (IPAC) range of floor standing units has been developed to satisfy the exacting standards

for full function air conditioned environments.

Floor Standing Range

Invicta Precision Air Control