RDF 500kg, RSF 1000kg, (for ROF racks deep

1200mm 1000kg), RHF 1500kg, color black RAL9005 (optionally light gray RAL 7035). For detailed technical information on RSF, RDF, RHF and ROF racks please refer to appropriate data sheets.

RHF‑42‑80/10P‑WWWWA‑2EF‑H

ROF‑45‑60/100‑WWWWA‑205‑H

ROF‑42‑60/120‑WWWWA‑20A‑H

ROF‑42‑80/10C‑WWWWA‑205‑H

ROF‑45‑80/10C‑WWWWA‑205‑H

ROF‑42‑80/12C‑WWWWA‑20A‑H

RDF‑45‑80/10C‑WWWWA‑2H5‑H

RDF‑42‑80/12C‑WWWWA‑2H5‑H

RSF‑45‑60/10T‑WWWWA‑2EA‑H

RSF‑42‑60/12T‑WWWWA‑2EA‑H

RSF‑42‑80/10U‑WWWWA‑2EA‑H

RSF‑45‑80/10U‑WWWWA‑2EA‑H

RSF‑42‑80/12U‑WWWWA‑2EA‑H

Rear vented door (83% perf. rate) with multipoint swivel handle lock (universal key)

Removable sheet steel side panels with lock (universal key)

Two pairs of 19" vertical sliding extrusions

Top and bottom openings for cable entry; (only ROF racks with fixed plates)

Adjustable feet as standard; recommended plinth or plinth with filter (not included)

Monitoring of containment and in cabinet environmental conditions

42U to 48U 600 mm or 800 mm wide cabinets 1000 mm or 1200 mm

deep cabinets

Air separation frames 150 mm or 200 mm deep

Air containment system 1200 mm or 1800 mm standard

83% super vented front and rear door (or solid rear door when used with

plenum return and chimney)

1200 mm or 1800 mm aisle spacing

Double brush grommets for cable entries

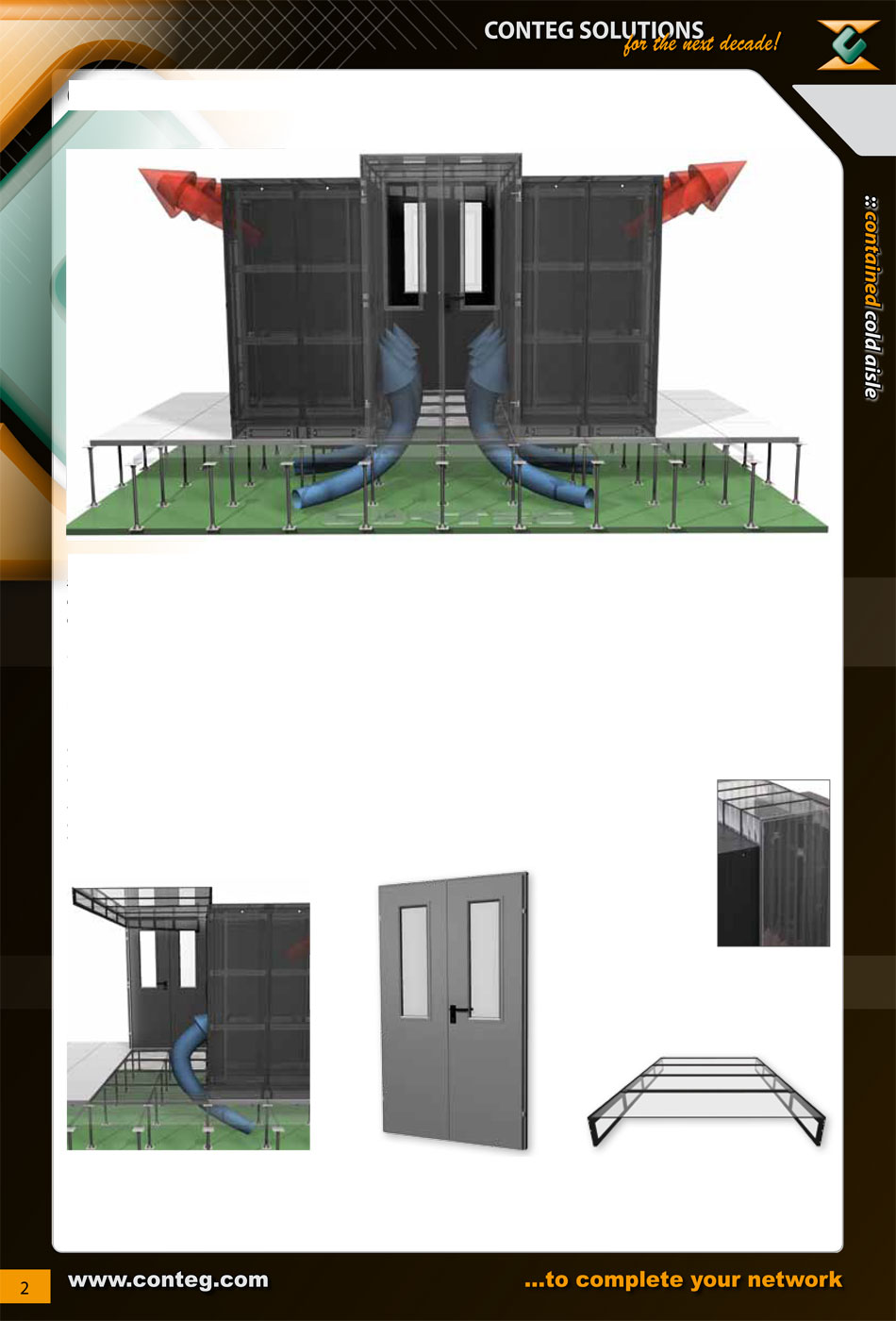

Contained aisle door Encloses cold aisle ends whilst providing access to the cold aisle interior

Contained aisle roof To seal top of aisle between opposing racks to prevent cold and warm air from mixing

Automatic door handle ADH makes the access into the aisle easier as well as it increases the safety

Cable entries Products for passage of cabling/pipes through raised floor with minimal loss of air pressure

Modular plinths Replace adjustable feet and are used as stabilizing and aesthetic element

Air separation frames Prevent by‑pass airflow between column and 19" extrusion to optimize cooling of equipment

Brackets Needed when vertical PDU installation into rack is planned

Blank panels Prevent cold air by‑pass through unused U positions

RDF series 19" distribution racks PREMIUM rack series provides maximum compatibility with Targeted Cooling solutions and developed developed for cabling support; load rating up to 500kg

RHF series 19" distribution racks PREMIUM rack series provides ultra high load rating up to 1500kg

ROF series 19 distribution racks OPTIMAL rack series, highly configurable with load rating up to 500kg, for racks deep 1200mm 1200mm 1000kg

In the Contained Aisle design the cold air is produced by central cooling

system with perimeter mounted CRAC/CRAH units. The raised floor is used

as a cold air handling plenum and the cold air enters the aisle via perforated floor tiles. If, from any reason, the raised floor cannot be used, the cold air can be produced locally by in‑row side mount cooling units installed directly in the row of racks. This solution is currently very popular as it can address very high heat loads.

By using the roof the cold air is trapped in the contained aisle, the roof also efficiently blocks the hot air to re‑enter the aisle

Dual leaf opening door allow access into the

contained aisle, it can be equipped by automatic

handling systems optionally

Cold air is delivered to the cold aisle using the raised

floor as a cold air handling plenum, the hot air is blown out on the back side to the data center room, roof and doors are used to prevent mixing hot and cold air

polycarbonate panels on

the top of the roof. Vertical side

sections of the roof feature PVC foil strips, which can be easily cut to the required length. Flexible Contained Aisle can work with standard aisle door (see above) or with PVC foil strips instead of standard door. Contact us for more information

Modular Contained Aisle

system is available upon request. This system is the ideal solution when a row of racks with different heights or even with gaps because of missing racks is required to be contained. System is based on self‑supporting construction with clear

should a fire be detected within a contained aisle, you would want to ensure that doors are closed to contain the suppressant within the affected aisle. Obviously, this requires co‑ordination with the designers of the access control, building management and fire suppression system but gives you an idea of the flexibility that is available with the CONTEG contained aisle system.

designed to support racks of 42 and 45U heights. The transparent sections are manufactured from clear poly carbonate to ensure that light can pass easily into the contained aisle.

As an option, the Contained Aisle system can be

fitted with automatic door handlers and integrated with the access control system, environmental monitoring system and fire alarm to ensure that the doors are opened or closed automatically. For example, in the case of a cooling system failure it would be beneficial to open the doors of the cold

aisle to allow environmental air to be available to the equipment for cooling and to limit the rate of equipment temperature increase. However

With CONTEG Contained Aisle solution, the modular containment system is used to physically separate cooled air from hot exhaust by forming a cold plenum space and preventing mixing of hot and cold air, thereby eliminating hot‑spots. The contained aisle solution can be deployed where higher density loads are collocated to ensure that all available cooling air is directed to the cabinets. It can also be combined with CONTEG Side Mount Cooling Units to produce cold air locally and ensure that all cold air produced passes through the equipment. The system is designed to work with RSF/RDF/RHF/RSB/ROF rack series the basis of CONTEGs data center solutions, and it is

One of the potential drawbacks of the Hot / Cold Aisle approach is the possibility of warm air recirculation due to insufficient static pressure within the raised floor or a lower than optimal ceiling clearance preventing adequate stratification of warm air. Of course, whether this actually occurs or not depends on many variables, however when facing this type of design challenge it makes engineering and financial sense to form a physical barrier between cold and warm air streams

CONTAINED COLD AISLE

CONTAINED COLD AISLE

UAE +971 2 5557351 +971 4 3352995 +971 4 8831401 OMAN +968 24 750205 QATAR +974 44150543

version: 08-04-2011