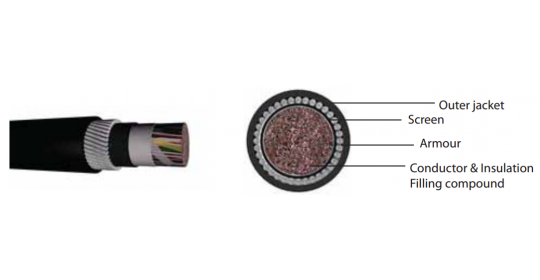

- Telephone Cable with cellular polyethylene insulation, jelly filled with petroleum jelly and a polyethylene coating.

- For use in the Local Distribution network.

- Insulated conductors uniformly twisted together to form a pair.

- The water resistant filling compound is applied to the air spaces within the cable core to provide the water-proofness

- Wrapping is applied over the cable core.

- A flat aluminium foil coated with copolymer on both sides is applied longitudinally over the core covering as screen.

- Black linear-low density polyethylene compound is extruded over the screen.

Physical Description

Conductors | Solid annealed bare copper conductors conforming to CCITT Yellow |

Insulation | Foam–skin polyethylene |

Cable Assembly | Twisted pairs ,cabled in a circular form |

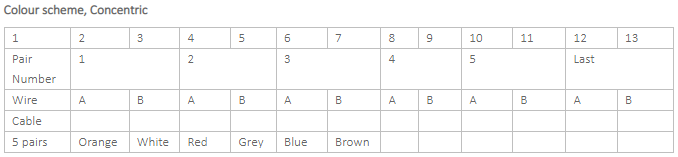

Color Code | As indicated below |

Filling | Water resistant lling compound, applied to the gaps between the pairs |

Tape wrap | Non hygroscopic polyester tape, wrapped with 25% overlap |

Identification | Manufacturer name and year of manufacture |

Flooding | Water resistant flooding compound , applied between the core wrap and |

Screen ( Shield) | Two side Copolymer coated aluminum foil laid longitudinally, bonded |

Inner Sheath | Black Low Density PE |

Armouring | Galvanized steel wire armouring |

Outer Sheath | Black Low Density PE |

Surface Marking | Telephone symbol, length marking, telephone symbol |

Mechanical Parameters of basic conductors

Nominal Conductor Diameter (mm) | 0.5 |

Maximum Conductor Diameter (mm) | 0.51 |

Minimum Conductor Elongation, % | 15 |

Insulated Conductor diameter (mm) | 0.9 |

Insulation ultimate tensile force minimum (N) | 2 |

Electrical Properties

DC resistance @20˚C Ohm/km Maximum Average | 91 |

DC resistance @20˚C Ohm/km Maximum for 1% of cases | 96 |

Mutual Capacitance nF/km, max Average | 53 |

Mutual Capacitance nF/km, max for 1% of cases | 60 |

Pair to pair capacitance unbalance, pF max | 275 |

Insulation Resistance, 500V DC Minimum Mohm.km | 1500 |

Colour codes of unit

Pair No | Colour of conductor insulation | |

| A – wire | B – wire |

1 | White | Blue |

2 | White | Orange |

3 | White | Green |

4 | White | Brown |

5 | White | Grey |

6 | Red | Blue |

7 | Red | Orange |

8 | Red | Green |

9 | Red | Brown |

10 | Red | Grey |

Colour codes of tape lappings, Unit

1 | Blue |

2 | Orange |

3 | Green |

4 | Brown |

5 | Grey |

6 | White |

7 | Red |

8 | Black |

9 | Yellow |

10 | Violet |

Cable External Jellyfilled Screened Armoured 50Pr 0.5mm

Related Product

Cable 2C,16AWG Solid Bare CU2/C TFP75C 300V Plenum -305m/Rl.

Specifications: Cable Type FPLP Cond. Size 16 A..

Cable RG11,CCTV,14AWG, CU COND.,95% BC,BRAID Shield-305m/Rl.

Description:Conductors: 14 AWG (1/.064) Solid Bare Copper.Rating: CL2/UL-1581.Dielectric: Foam Polye..

Cable 1P, 16AWG, Unshielded, PVC R50120-1A -305m/Roll.

- Cable 1P, 16AWG, Unshielded, PVC R50120-1A -305m/Roll...

Cable Studio 4x4x0.20sqmm Pegasus PVC Black.

It is the multipair for the ambitious studio professional who dislikes to compromise on linearity an..