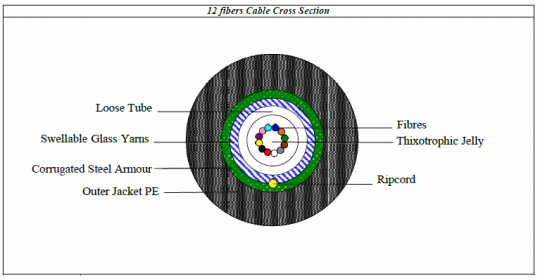

Cable Type: Loose Tube, Outdoor F/O Cable

- 12 fibers armored outdoor fiber optic cable,

- Thixotrophic jelly filled loose tubes,

- Central loose tube design,

- Swellable glass yarn as strength member and low rodent protection,

- Corrugated steel armor,

- Outer jacket is made of medium density polyethylene,

- Ripcord is inserted for easy jackets removal.

Fiber Type | MM 62.5/125 µm |

Central strength member | No central strength member |

Tube material | PBT ( Polybutylene Terephtalate) |

Color of loose tube | Natural |

Color of fibers in per tube | Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Violet, Rose, Aqua |

Tube filling compound | Thixotropic jelly |

Tape wrap | - |

Strength elements and low rodent protection | Swellable glass yarns |

Ripcord | Aramid cord |

Identification tape marking | As a customer request |

Inner jacket | No inner jacket |

Armor | Corrugated steel tape |

Outer jacket | Black MDPE, thickness nominal 1.5±0.1 mm. |

Surface marking | As a customer request |

Fiber Count | Tube Outer/Inner Diameter (mm) | Cable Diameter (mm) | Cable Weigth (kg/km) |

12 | 3.0/2.0* | 9.0* | 86* |

*:Tolerance is ±10%

Mechanical and Environmental Properties | ||

Physical tests | Value | Standard |

Tensile Strength | 1500 N | IEC 60794-1-E1 |

Impact Resistance | 5 impacts | IEC 60794-1-E4 |

Crush Resistance | 220 N/cm | IEC 60794-1-E3 |

Bend Radius (during installation) | 30x cable diameter | IEC 60794-1-E11 |

Bend Radius (during Service) | 15x cable diameter | IEC 60794-1-E11 |

Storage and Transportation Temperature | -40 to +70 °C | |

Installation Temperature | -5 to +50 °C | |

Operation Temperature | -30 to +70 °C | |

Reel Marking | As a customer request | |

Metal Plate at drum | As a customer request | |

62.5/125 µm MM OPTICAL FIBER | |

PROPERTIES | SPECIFIED VALUES |

Attenuations (max) | 3.5 dB/km (850 nm) 1.5 dB/km (1300 nm) |

Bandwidth (min) | 200 MHz.km(850 nm) 500 MHz.km(1300 nm) |

Numerical Aparature | 0.275±0,015 |

Core Diameter | 62.5±3 mm |

Cladding Diameter | 125±3mm |

Core/Clad Concentricity error (max) | % 6 |

Cladding non-circularity (max) | %2 |

Coating Diameter | 250±15 mm |

Proof Test | 8.4 N |

Proof Test strain | %1.00 |

Cable External FO 12C 62.5/125 CLT Steel ARM - Black

Related Product

Cable 2C,16AWG Solid Bare CU2/C TFP75C 300V Plenum -305m/Rl.

Specifications: Cable Type FPLP Cond. Size 16 A..

Cable RG11,CCTV,14AWG, CU COND.,95% BC,BRAID Shield-305m/Rl.

Description:Conductors: 14 AWG (1/.064) Solid Bare Copper.Rating: CL2/UL-1581.Dielectric: Foam Polye..

Cable 1P, 16AWG, Unshielded, PVC R50120-1A -305m/Roll.

- Cable 1P, 16AWG, Unshielded, PVC R50120-1A -305m/Roll...

Cable Studio 4x4x0.20sqmm Pegasus PVC Black.

It is the multipair for the ambitious studio professional who dislikes to compromise on linearity an..